Inventory Control of Formwork

Formwork is a die or a mould which has been used to give desired shape or form to green concrete as per the

requirements and also to support to the concrete until the concrete attains sufficient strength to carry its own weight.

Prime responsibility is to ensure optimum utilization of formwork to increase its utilization value.

I) Mainly it depends upon how to use and handle the formwork during work in progress.

II) It is the duty of site personnel to contribute towards the optimum utilization of materials through proper

inventory management. The objectives of inventory control is to ensure adequate monitoring and verification

of inventories for efficient acquisition and effective reuse of those materials.

Stages through which inventory control of formwork can be done at site are:

RECEIVING PROCESS

1. Received Materials must be checked component wise and verified with the challan.

2. Store personnel and Shuttering supervisor must be present to monitor the entire material receiving process.

3. All the materials must be received item-wise in their regular unit of measurement and dimensions as well as in

tonnage.

4. Any discrepancy / shortage in receiving quantity w.r.t. challan quantity shall be immediately communicated to the

dispatching sites and Formwork Cell at R.O.

5. If the receiving site receives damaged materials, then they must inform to Formwork Cell with proper details and

photographs.

6. Receive of material must be done through electronically generated challan.

STORING PROCESS

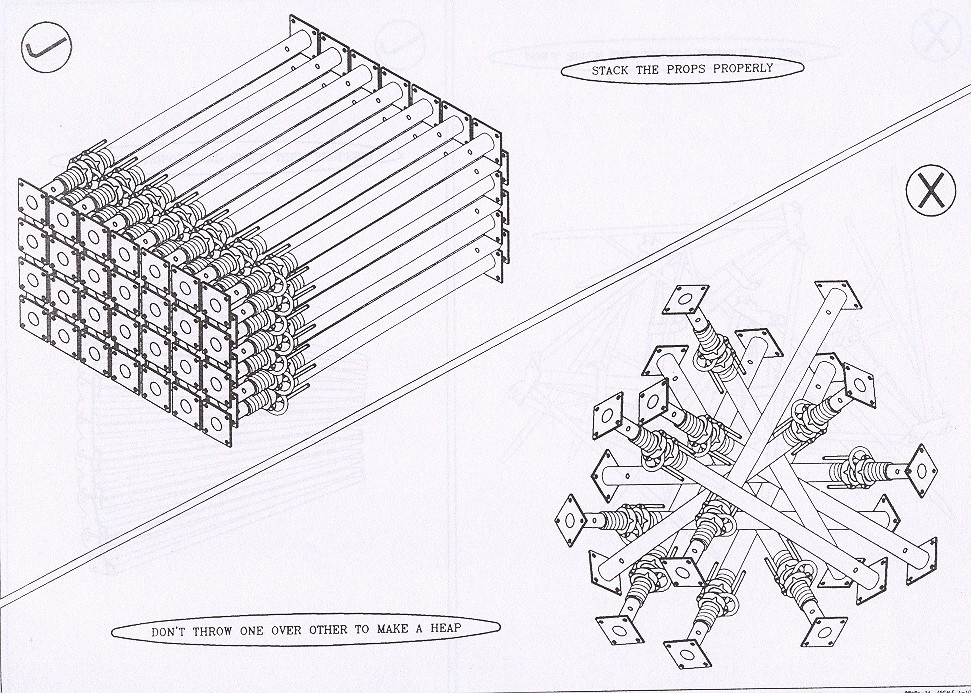

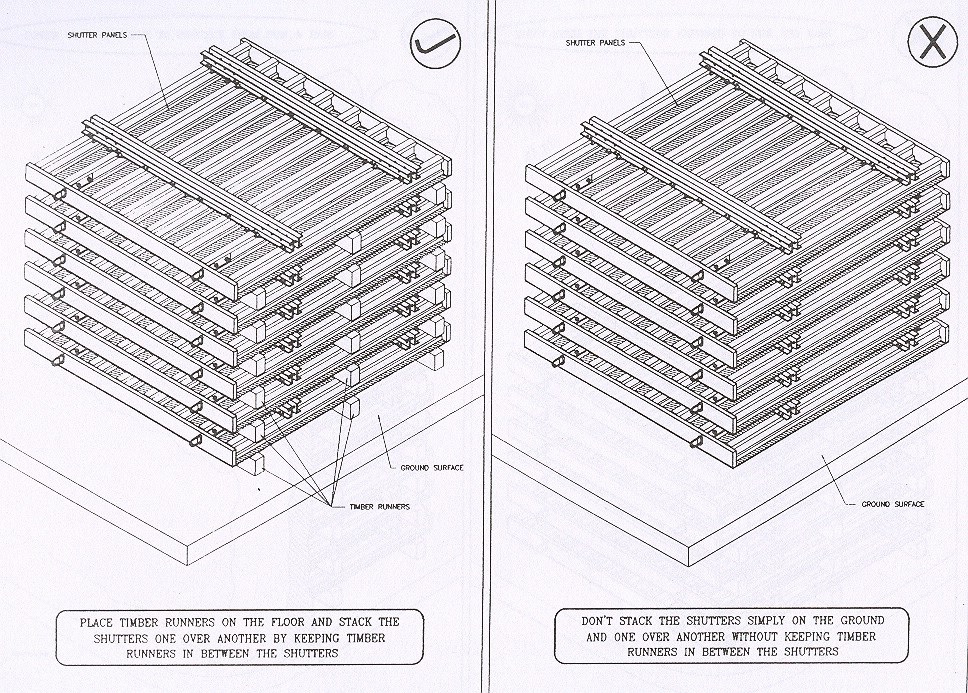

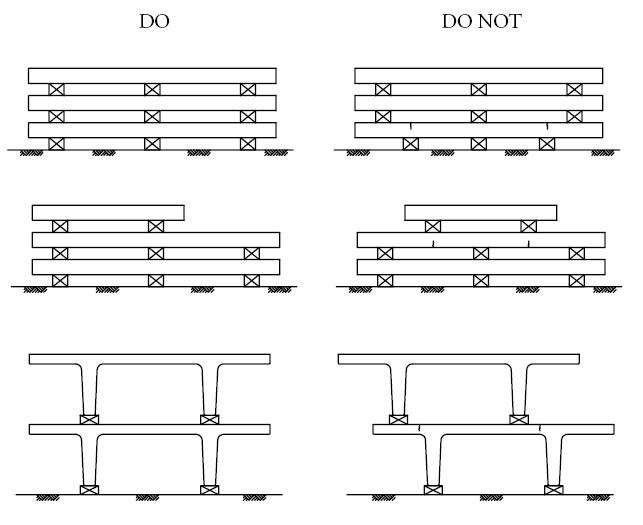

1. Usable, repairable and not repairable materials should be segregated and shall be stacked separately.

2. All idle inventory of shuttering and scaffolding materials of the site are required to be stacked item wise after

proper cleaning of materials.

3. Records of all stacked materials shall be maintained in their regular unit of measurement & dimensions.

4. The materials should always stacked at some height from ground level for better handling and protection from

water and rust. It should not be stacked near the cement or lime stone.

Proper stacking helps in:

- Easy reconciliation

- Faster retrieval of material

- Better space management

- Improving work culture

- Avoiding wasteful expenditure

- Preventing loss of material

- Protection of materials i.e. improves life of materials

- Enabling easy maintenance

5. Repairable shuttering & Scaffolding materials shall be initiated for further repairing at site in consultation with the

section-in-charge for their further reuse.

6. Unused / lying idle shuttering & scaffolding materials at different work location of site shall be collected &

properly stacked at storing location time to time

7. In case of theft / pilferage of materials, immediate F.I.R. shall be lodged at local police station.

8. Surplus stock and their release programme (if any) should be send to R.O.(Formwork Cell) periodically after

discussing the same with planning dept. and project-in-charge.

DISPATCHING PROCESS

1. Approval for the dispatch programme must be obtained from R.O duly before dispatch. No materials can be

dispatched from site without prior approval.

2. Before dispatch of materials, all the materials must be cleaned properly (free from concrete).

3. Materials should be dispatched according to the dispatch programme. Unusable and Damaged materials shall not

be included in consignment.

4. While loading of materials to commercial vehicles, the materials must be loaded component wise in their regular

unit of measurement and dimensions as well as in tonnage.

5. The hard copies of challan & item-wise list of consignment must be sent along with the vehicles and materials.

6. After dispatching of materials e-challan shall be immediately send to R.O.